Analytical approaches must keep pace to ensure the identity, safety, and efficacy of evolving mRNA candidates.

Cynthia A. Challener, PhD, is a contributing editor to BioPharm International.

Analytical approaches must keep pace to ensure the identity, safety, and efficacy of evolving mRNA candidates.

Multispecific analysis is complex but can be achieved using appropriate strategies.

Timing is everything, and it might be ideal for acceleration of real-time monitoring solutions.

Surrogate analytics are no longer sufficient, as simple inexpensive real-time analytics are urgently needed for high value products.

Speed-to-market, capacity, technology development, and increased investment top the list.

Alternative materials, as well as supply-chain planning, are essential to ensure a reliable supply for parenteral drug packaging.

The benefits of single-use technologies for upstream viral-vector processes clearly outweigh their disadvantages.

Advances in technology are accelerating the development and manufacture of subunit vaccines, an established class of vaccines.

Understanding the process and product goals is just the first step to a holistic approach to process development.

Contract manufacturers play a key role in the production of lipid nanoparticles for RNA vaccines.

Mass spectrometry and automation are growing in importance for protein characterization, but further improvements are still needed.

Biopharmaceutical companies and contract manufacturers respond to changing demand dynamics for upstream bioprocessing capacity.

In a pandemic, genetic vaccines offer several advantages over traditional approaches.

Plasma-based proteins and cell-based therapies have significant potential to address unmet medical needs.

Connected, integrated bioprocessing enterprises with greater data analytics capabilities are coming.

Clear understanding of what exactly the biomolecule entails is essential.

A holistic approach to validation and quality assurance is essential.

PAT advances are enabling improved process understanding, process control, and error prevention.

A balance must be achieved between debris and impurity removal and maximizing product quality and yield.

Facility and equipment design are important, but the team and its experience matter most.

New therapeutics modalities and the need for greater process efficiency are driving technology development.

Many antibody-drug conjugate therapies are in the pipeline; only a handful have been approved. What are the bottlenecks?

RNA is easier to manipulate than DNA but challenging to deliver to the right cells.

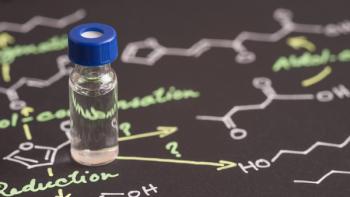

Identifying the source, assessing the risk, and removing residual impurities requires a strategic approach.

Therapies for early and late treatment and passive immunization of COVID-19 are needed and can be developed using antibodies from recovered patients.

Next-generation therapeutics and regulatory requirements create demand for complex, fit-for-purpose tests.

Biopharma companies responding to the COVID-19 outbreak think accelerating the development of vaccines is safe.

Experience, communication, collaboration, transparency, planning, and prioritization contribute to success.

Ensuring the quality of data in process monitoring and control systems starts in process development phases.

Analytical solutions are improving for raw material testing, process development, drug product release, and more.