Introduction; Materials and Methods

Introduction; Materials and Methods

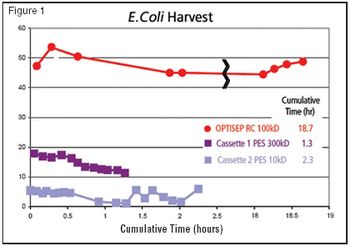

Increasing efficiency and throughput in downstream separation and purification performance is currently a major focus in the biopharmaceutical industry. Traditional TFF systems cannot be scaled in a linear fashion to meet the projected demand for fermentation and cell culture based products. NCSRT has created a patented line of filtration solutions that address the bottlenecks currently experienced as biopharmaceutical products scale up from clinical trials to blockbuster production quantities.

Cytovance Biologics is a contract biopharmaceutical process development and cGMP manufacturing organization specializing in products derived from mammalian cell culture. Our highly experienced team of experts is committed to providing best-in-class services that help our customers move recombinant protein and antibody products rapidly and cost-effectively into and through clinical development. We employ a collaborative and flexible approach and business practices that meet the long-term needs of our customers and deliver long-term value and support.

Introduction, Capabilities

A new universal RP-HPLC column for peptide purification, and the use of novel flow-through media for the removal of acidic ion pairing agents and peptide free base formation are reported. The use of these two products, with SOPs, can substantially increase the throughput of peptide manufacture.

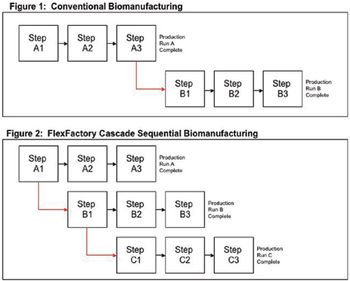

Cook Pharmica LLC is a biopharmaceutical contract manufacturer of mammalian cell-culture products. Cook Pharmica's mission is to provide process development, flexible manufacturing, and analytical services to the global biotech community, enabling its partners to bring their life-saving discoveries to patients. Founded in 2004, Cook Pharmica is a privately held, wholly-owned subsidiary of Cook Incorporated.

Radio frequency identification (RFID) technology is a reliable, accurate method of conveying critical information from point to point. Well established digital data transfer standards ensure complete and accurate exchange of critical data at almost instantaneous speeds. Unlike bar codes, RFID possesses larger data storage capability meaning more information is available. RFID tags are embedded in the filters which make the data available at point of use, where you need it, and inherently less susceptible to mechanical damage. Finally, RFID does not require a specific orientation to be read, eliminating the need for human intervention, thus lending itself to reliable automated processes.

A new, very high capacity cation exchange resin* for process scale applications was developed by the researchers at Tosoh Corporation. This resin, with dynamic binding capacities approaching 145 mg/mL for IgG molecules, is the newest member of the Toyopearl product line.

Abstract: Sparta Systems' TrackWise quality and compliance management software (QMS) helps global biopharmaceutical companies reduce risk, achieve compliance, and lower costs. TrackWise streamlines processes by improving visibility, traceability, and accountability through structured workflow, escalation and reporting.

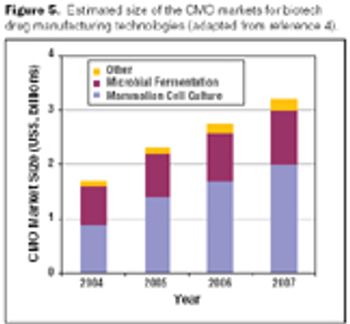

Biologics manufacturing is a technologically complex, highly regulated process. In comparison to small-molecule manufacturing, biologics manufacturing requires far more planning, investment, and skilled personnel and, therefore, can be much riskier. For biotech companies requiring such manufacturing capabilities and experience, partnering with a biologics-focused contract manufacturing organization (CMO) can be a good solution.

Cobra Biomanufacturing is dedicated to designing robust processes that deliver high-quality preclinical and clinical biopharmaceutical products for its international life-sciences customers. From proteins and viruses to DNA and cells, Cobra offers a full range of biomanufacturing services and has established an enviable track record in cGMP manufacturing.